Description

ELECTRODEIONIZATION (EDI SYSTEM) - ELECTROPURE EDI

EXL: High flow rate EDI for Power Generation and Industrial applications

Manufacturers: SNOWPURE - USA

Model: EXL-550, EXL-650, EXL-750, EXL-850

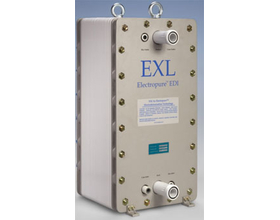

Electropure™ EDI: EXL

High flow rate EDI for Power Generation and Industrial applications

EXL by Electropure™ modules are designed to be the highest flow Electrodeionization modules on the market. EXL modules can handle flow rates up to 8 m3/hr (35 gpm) depending on the specific requirements of the customer. EXL was in limited release in China as of January 2009.

EXL

- Electropure™ EDI technology with the same physical profile as E-Cell® MK3 and Ionpure® LX modules.

- Includes SnowPure’s patented Excellion™ membranes

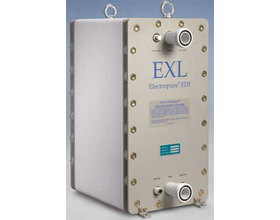

- EXL feed and product ports have 4 options:

- MAXI 1″ Sanitary Tri-Clamp® (E-Cell® MK3 replacement) for EXL-510-HTS, 610-HTS, 650

- 32DN25 1” (or 25mm) +GF+ Georg Fischer Union for EXL-650

- 40DN32 1-1/4” (or 32mm) +GF+ Georg Fischer Union for EXL-750 & 850

- DN40 1-1/2″ Sanitary Connection for EXL-510-HTS, 610-HTS, 710-HTS, 750, 850,

- Note: any of the above 4 fitting options work with all EXL models interchangeably.

See our EXL Product Fittings Brochure for details.

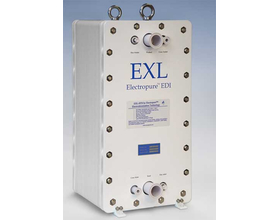

- +GF+ unions can connect to:

- Metric, US, or Japanese pipe

- PVC, PP, PVDF, or SS, threaded or welded pipe

- EXL concentrate and electrode ports options are flexible metric tubing (John Guest) or US tubing (John Guest)

- EXL has permanent seals on each chamber and requires no torqueing

EXL Power, Industrial, & Sanitary Pharmaceutical EDI

EXL-550 – click for data sheets

EXL-650

EXL-750

EXL-850

EXL HTS High-Temperature Pharmaceutical EDI

EXL-510-HTS – click for data sheets

EXL-610-HTS

EXL-710-HTS

EXL-810-HTS

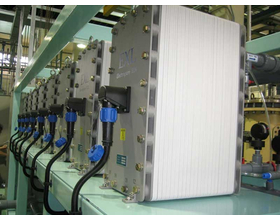

Applications

EDI is useful for any application that requires constant and economic removal of water impurities without using dangerous chemical. Some examples are:

- Reuse of residual water in food and beverages industry

- Chemical production

- Biotechnology

- Electronics

- Cosmetic

- Laboratories

- Pharmaceutical industry

- Boiler Feed Water

- Reduction of ionizable SiO2 and TOC (total organic carbon)

Since installation EDI units perform quite reliably, providing the customers with high purity production water for either power plant boiler feed or microchip rinse water. The water produced has met or exceeded customer high-purity water specifications. In addition, when a diluite stream cleaning was required as result of fouling, product quality was completely recovered.