Description

ELECTRODEIONIZATION (EDI SYSTEM) - ELECTROPURE EDI

XL-HTS, EXL-HTS: High Temperature Stable EDI for Pharmaceutical and Laborator

Manufacturers: SNOWPURE - USA

| MODEL | FLOW RATE |

| EXL-710-HTS | 5.0 - 8.0 m3/h |

| EXL-610-HTS | 3.5 - 5.5 m3/h |

| EXL-510-HTS | 2.5 - 4.0 m3/h |

| XL-500-HTS | 1.3 - 2.5 m3/h |

| XL-400-HTS | 0.7 - 1.5 m3/h |

| XL-300-HTS | 300 - 1000 lit/h |

| XL-200-HTS | 100 - 300 lit/h |

| XL-100-HTS | 50 - 150 lit/h |

Ứng dụng: Chuyên dùng khử khoáng cho xử lý nước cấp siêu tinh khiết cho ngành Dược Phẩm. Làm sạch vi sinh bằng nước nóng đến 85 độ C.

Electropure™ EDI: XL-HTS

High Temperature Stable EDI for Pharmaceutical and Laboratory

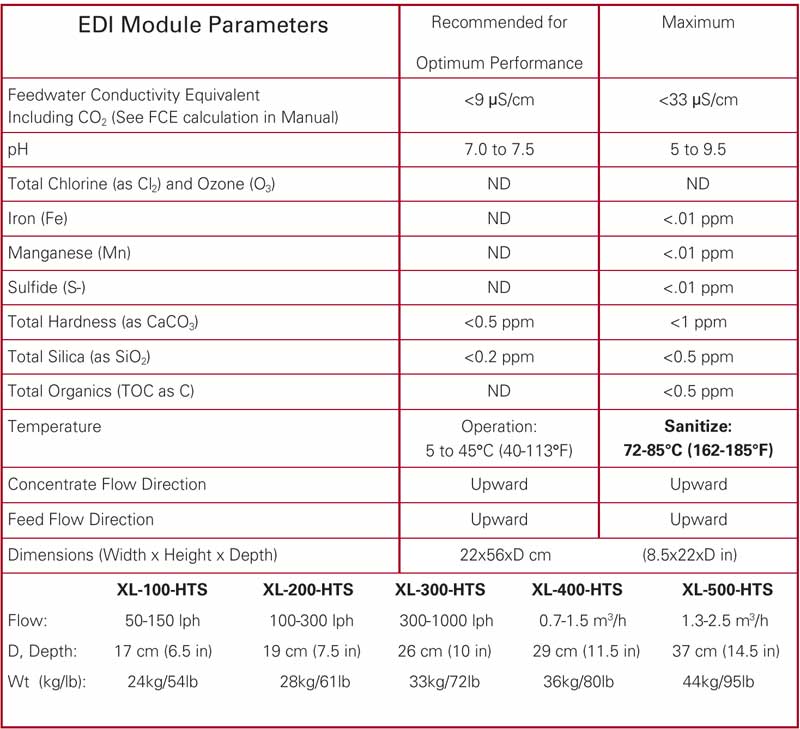

XL-HTS High Temperature Stable Sanitary Modules by Electropure™ products cover a range of flows from 50 l/h to 8 m3/hr. depending on the specific requirements of the customer. These are designed for periodic cold or hot sanitization. The modules are stable for heat cycling up to 80 degrees C, for over 104 cycles.

XL-HTS

- Feed and product ports are 1-inch (1 ") Ladish Sanitary Fittings.

- Modules come with sanitary clamps, seals and stainless steel covers

- Simple systems can be built with multiple modules in parallel.

- Modules are manufactured with materials that are compliant with FDA CFR 21.

- Non-functional show models are available for purchase on request.

Electropure™ EDI XL-HTS Brochure

Applications

EDI is useful for any application that requires constant and economic removal of water impurities without using dangerous chemical. Some examples are:

- Reuse of residual water in food and beverages industry

- Chemical production

- Biotechnology

- Electronics

- Cosmetic

- Laboratories

- Pharmaceutical industry

- Boiler Feed Water

- Reduction of ionizable SiO2 and TOC (total organic carbon)

Since installation EDI units perform quite reliably, providing the customers with high purity production water for either power plant boiler feed or microchip rinse water. The water produced has met or exceeded customer high-purity water specifications. In addition, when a diluite stream cleaning was required as result of fouling, product quality was completely recovered.