Description

AS-DEHYDRATOR MULTI-DISC SCREW PRESS

DEWATING PRESS & THICKNESS

Manufacturers: ASIO – Czech

Model: AS-131, AS-132, AS-201, AS-202, AS-301, AS-302, AS-303, AS-351, AS-352, AS-353, AS-401, AS-402, AS-403, AS-404.

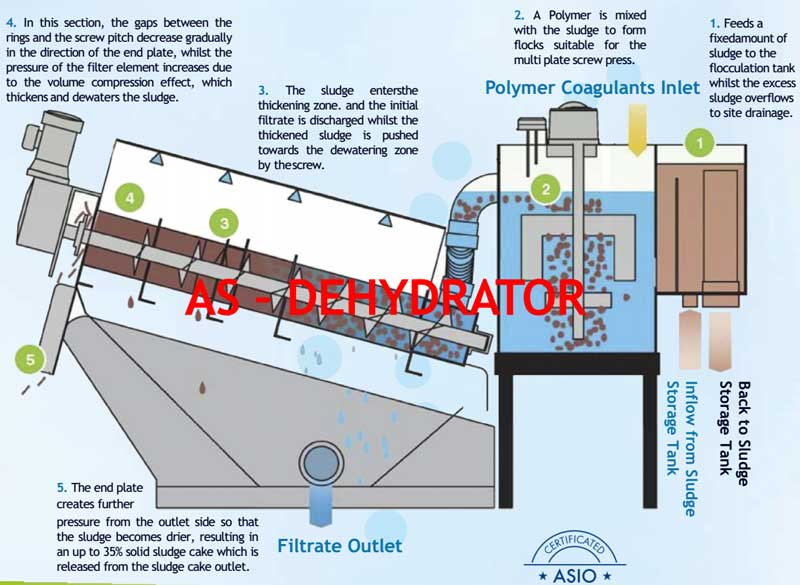

The sludge dewatering process, the core of which is AS–DEHYDRATOR, is characteristic for its automated operations at low operating costs. Sludge is pumped into the dehydrator inlet vessel, from where it flows over a triangular overflow into the dehydrator flocculation tank. Any sludge quantities exceeding the equipment capacity are returned through the safety overflow back. The flocculation tank is stirred with a low-speed paddle mixer and a polymeric flocculant is dosed into the incoming sludge. The flocculant solution is prepared directly at the wastewater treatment plant by mixing of the agent concentrate with water in an independent tank; then it is dosed in sufficient quantities by a dosing pump into the dehydrator. By the reaction of the flocculant with the sludge, clearly defined flakes are formed in the dehydrator flocculation tank to be subsequently brought into the dewatering drum. The drum consists of a spiral conveyor enclosed in a tube, where fixed and moving baffles take turns. By the spiral movements, the sludge is moved to a thrust plate; at the same time, the water stream squeezed out of the sludge flows away among the baffles. The filtrate, i.e. the water squeezed out of the sludge, is brought back to the wastewater treatment process, while the dewatered sludge falls out at the drum end hopper and its dry matter is usually 20%, which represents a solid mass. The dewatered sludge is then usually placed into a container and it can be used, for instance, in Oxic tank. It is necessary to consider that the increase in the dry matter content from 0,2% to 20% represents a hundredfold decrease in the sludge volume, which results in a considerable reduction of transport and disposal costs.

AS–DEHYDRATOR advantages

The dehydrator is designed in order to prevent its clogging, which minimises the de-mand for washing water and servicing. At the same time, the dehydrator absorbed power is very low. Uses around 70% less energy than a centrifuge and 80% less water than a belt press to process the same volume of sludge.

The dehydrator enables dewatering not only of biological sludge but also chemical and flotation sludge types.

A thickening zone is built in the dehydrator, which eliminates the necessity of any sludge thickening before the inlet into the equipment. Together with accessories, the dewatering drum forms a compact structure that make possible to minimise space requirements.

The equipment removes water from the sludge with low concentrations of dry matter (directly from the activation process) and produces thus a sludge cake containing of about 20% of dry matter.

Built self-cleaning system handles oily sludge without clogging and requires no rinsing water to prevent clogging.

The dehydrator is capable of operating in a continuous round-the-clock automated mode, incl. the flocculant preparation and dosing. Time necessary for servicing and maintenance is minimal (approx. 5 minutes per day).