Description

TÁI SỬ DỤNG XÚT (CAUSTIC) TRONG SẢN XUẤT BIA

BREWERY _ THE CAUSTIC RECOVERY PROCESS

Download Process Separations _ KOCH MEMBRANE

Brochue hệ thống thu hồi NaOH _ Caustic Recovery _ Caustic-COR

Công ty Môi Trường Hành Trình Xanh hân hạnh là nhà nhập khẩu và phân phối độc quyền sản phẩm CÔNG NGHỆ THU HỒI XÚT (NAOH / Sodium hydroxide) + AXIT _ KOCH - USA tại Việt Nam. Chúng tôi cam kết cung cấp sản phẩm và dịch vụ tốt nhất tới Quý Khách hàng.

Filtration for a Better Future là cam kết của chúng tôi và cũng là động lực thúc đẩy chúng tôi liên tục cải tiến công nghệ để tạo ra sản phẩm giá trị cao nhất cho khách hàng của mình.

Với trên 50 năm kinh nghiệm, Koch Membrane Systems (KMS) đã tiên phong trong việc nghiên cứu phát triển các loại Màng Lọc như: SPIRAL, HOLLOW-FIBER và TUBULAR.

KMS là công ty hàng đầu thế giới về Công Nghệ Màng Lọc với nhà máy sản xuất và trung tâm nghiên cứu hiện đại nhất được đặt tại Wilmington, Massachusetts (USA).

Ngoài ra, Chúng tôi đã cung cấp Màng RO, NF, UF, MF trên toàn thế giới với hơn 400 loại sản phẩm khác nhau. KMS cam kết sản phẩm và dịch vụ khách hàng tốt nhất, giúp đạt hiệu quả vận hành tối đa với chi phí tối thiểu.

MÔ TẢ VỀ HỆ THỐNG LỌC BIA BẰNG LÕI LỌC PVPP

Regenerative beer stabilization using PVPP / Ổn định chất lượng Bia bằng cột lọc PVPP

If breweries decide in favor of recycling and for the related regenerative stabilization of beer using PVPP, it is necessary to invest in a separate beer stabilization system. Các nhà máy Bia thường ổn định Bia bằng lõi lọc PVPP.

The standard practice to date has been regenerative beer stabilization using a horizontal mesh or gap candle filter , slightly modified for the task of beer stabilization and connected directly downstream of the classical filtration process. / Thường sử dụng bộ lọc lưới ngang hoặc Lọc Nến

The process can be briefly described as follows: reusable PVPP is fed into the filtered beer directly after clarifying filtration, it removes tannins from the beer and is then removed from the beer by the beer stabilizing system. When a stabilizing cycle is complete and consequently all the PVPP has been added and the maximum pressure volume in the filter achieved, the beer is forced out of the system with deaerated water. Lõi lọc PVPP lọc Tannin ra khỏi bia, sau một khoảng thời gian lõi lọc bị ngẹt, lúc đó áp lên cao.

This is followed by the regeneration process for cross-linked PVPP. Reusable PVPP is purged with a 1% hot caustic solution; in doing so, enriched polyphenols are released to the caustic and thereby removed from the system. The regenerated and neutralized reusable PVPP passes to a purpose-built dosage tank for reuse. / Quá trình tái sinh lõi lọc PVPP sử dụng NaOH 1%, các polyphenol trên lõi lọc được giải phóng vào Xút (NaOH) => do đó được loại bỏ khỏi hệ thống. Lõi lọc PVPP được tái sử dụng. Và Xút (NaOH) có thể chuyển đến bể chứa có mục đích để tái sử dụng.

Lượng Xút (NaOH) sử dụng rất lớn => chi phí sản xuất tăng lên, đồng thời thải ra chất thải nguy hại.

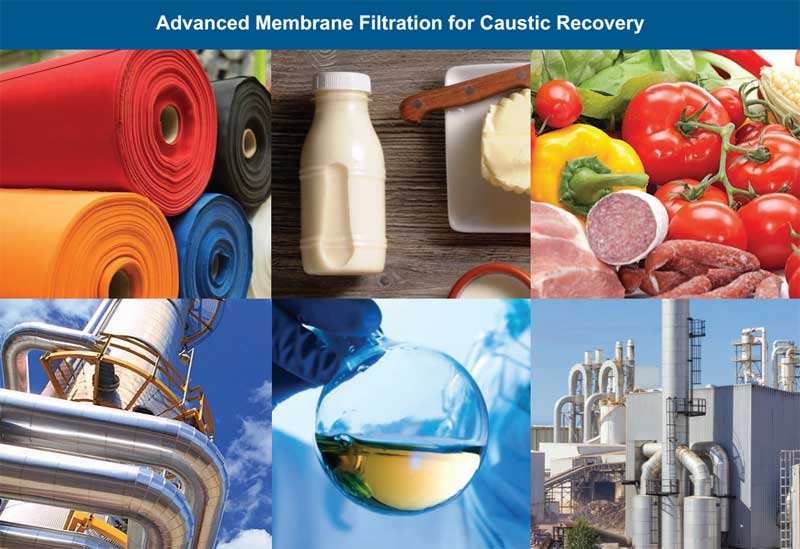

Causti-COR® Systems

How Much Is Your Caustic Really Costing You?

Membrane Technology Designed Specifcally for Caustic Recovery

Over 50 Years of Membrane Experience

Koch membrane systems (KMS) is a global leader in membrane fltration technologies with over 50 years of membrane experience and 20,000 system installations worldwide. We have applied our experence and expertise to develop our new Causti-COR® systems, designed specifcally to recover, purify and reuse caustic from food, beverage and industrial applications. These systems lower spending on caustic, reduce energy consumption, and are environmentally friendly to help your company comply with increasing stringent regulatory requirements.

SelRO®

The SelRO® chemically stable NF membranes are among our best-selling products, designed for robust performance and a long lifecycle. Commonly used in the pulp, paper, textile and other chemical industries, SelRO® elements are made to handle extreme acid and caustic conditions, and temperatures up to 160˚F (70˚C). Our pH stable spiral is the only product in the market with proven long-term compatibility in acid and caustic concentrations above 10%.

The SelRO family of spiral wound elements utilize a proprietary membrane developed by KMS using a highly crosslinked polymeric chemistry.

They demonstrate long membrane life while treating acids and bases with temperatures up to 160°F (70°C), and concentrations including:

- Sodium and potassium hydroxide (up to 20%)

- Sulfuric, nitric, hydrochloric, hydrofluoric and phosphoric acids or acid blends, up to 35%

- pH levels from 0-14

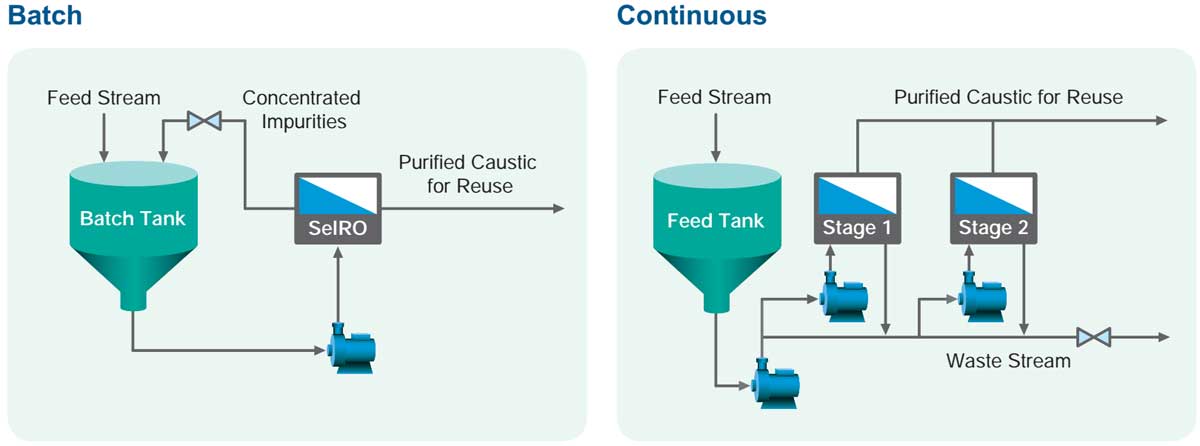

THE CAUSTIC RECOVERY PROCESS

- > 90% recovery

- > 90% COD reduction

- > 90% water and heat savings

- 80-90% hardness and carbonates reduction

- Colorless product

- Compact design

- Fast return on investment

- Modular design

SYSTEMS INFORMATION

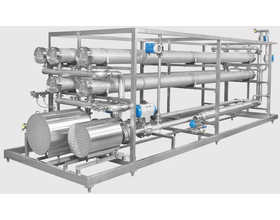

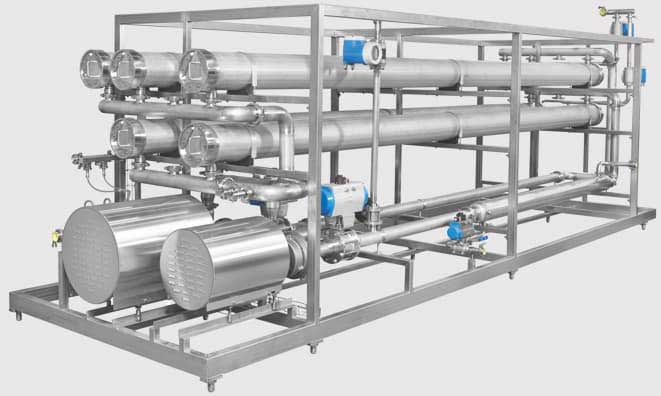

Causti-COR® systems use the KMS SelRO® spiral-wound products for acid and caustic recovery in various industries, including pulp, paper, textiles, pharmaceuticals, food, beverages and more. Causti-COR® systems produce high-quality effluent while fostering environmental sustainability, saving significant chemical costs, and reducing wastewater volumes.

Causti-COR Systems

The KMS Causti-COR Nanofltration Membrane Systems offer a cost effective, environmentally friendly way to recover the expensive caustic solutions used to clean process equipment.

Causti-COR systems utilize our patented SelRO® membranes to recover up to 95% of caustic for reuse by removing low molecular weight organic and inorganic contaminants.

Benefts of recycling caustic

- Less spending on caustic and acid materials

- Reduction in efuent volume

- Reduced waste treatment costs

- Lower energy consumption

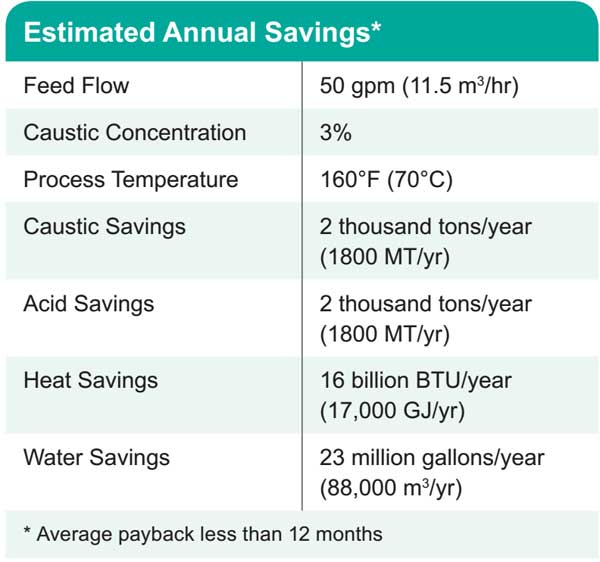

Estimated Annual Savings*

Caustic Systems

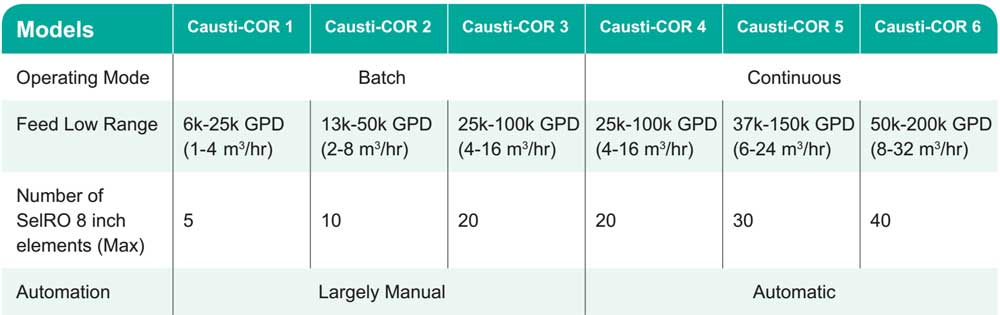

The Causti-COR® system family offers six models, including 3 small, simple to operate batch systems for small and medium flow rates between 1 and 15 m3/hr (10,000 – 100,000 GPD) and 3 larger, continuously

operated systems for medium and large feed flow rates between 4 and 32 m3/hr (25,000 – 200,000 GPD). Larger flow rates can be treated using custom-engineered systems.

Common Recovery Applications

- Pulp and paper

- Textile manufacturing

- Purifcation and mercerization

- Pharmaceutical

- Equipment cleaning

- Food processing

- Spent regeneration streams of resin columns and ion exchange operation

- Dairy, Food and Beverage

- Oil industry

DOWNLOAD DATASHEETS

SelRO® MPS-34 2.5" and 4" pH Stable NF Elements

SelRO MPS-34 8" pH Stable NF Elements

SelRO MPS-34 Sanitary 8" pH Stable NF Elements

SelRO MPS-36 2.5" and 4" pH Stable NF Elements

SelRO MPS-36 Sanitary 4” pH Stable NF Elements