Description

SUPER-COR® _ TUBULAR Membrane for Juice Processing...

|

|

Download Process Separations _ KOCH MEMBRANE

Brochue BEVERAGE Solutions: KOCH - USA

For over 50 years, Koch Membrane Systems has pioneered the advancement of SPIRAL, HOLLOW-FIBER and TUBULAR filtration membranes and systems through innovation, research and development. From our state-of-the-art manufacturing and development facility in Wilmington, Massachusetts, we invest in technology with a focus on improving membrane formulations, element construction and process applications. In the interest of fully understanding your unique filtration requirements, our experienced team works side-by-side with you to learn your objectives, evaluate the options and provide best-practice advice for installing, operating and maintaining your membranes for peak performance and long-term efficiency.

High-purity processing means better-tasting beverages.

KMS offers a multitude of efcient solutions that help beverage manufacturers concentrate, clarify, and purify products, from the treatment of incoming water to the fnal product. From water to wine, it’s smart technology that’s behind the world’s favorite beverages.

Juice Processing

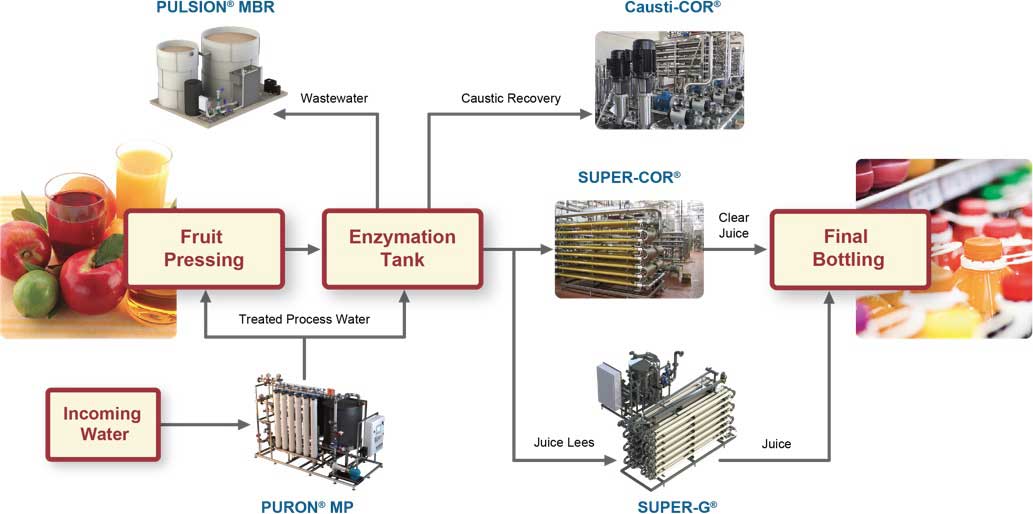

From processing golden, haze-free apple juice to ensuring excellent color passage in dark juices, KMS offers juice clarifcation technology for all juices and production requirements, providing signifcantly increased yields of higher-quality juice with less maintenance than conventional methods.

KMS membrane systems easily remove suspended solids, colloidal haze particles, microorganisms, and undesirable proteins, leaving a crystal clear, flavorful juice. Our systems offer fltered juice yields of 96-99%, producing more juice per bushel and higher profts per gallon without the need for diatomaceous earth (DE).

KMS juice clarifcation solutions are durable and long-lasting, which means optimal productivity, high flux, and high recovery.

Several of the world’s largest juice processors turn to KMS to help recover fruit solids and reduce bitterness in their juices. KMS has perfected a process that combines membrane separation and polymeric adsorption to remove limonin, hesperidins, and polyphenols from prime orange, grapefruit, tangerine, lemon, and lime juices, providing improved juice quality, consistency, and yield.

Bottled Water

KMS membrane systems offer superior pretreatment for beverage water, with hollow fiber ultrafltration providing excellent purifcation in a compact package that resistsparticulate buildup. With KMS membrane systems, the water you produce will be clean and safe, with a reduced environmental impact.

Wine

KMS is a trendsetter in putting membranes to use in the wine industry, working closely with winemakers to enhance the organoleptic and aesthetic characteristics of their products. Using crossflow fltration with KMS membranes offers excellent throughput and eliminates the need for using DE or filter sheets. Now a gentle, one-step process can reduce your processing costs while boosting the wine’s quality and color intensity.

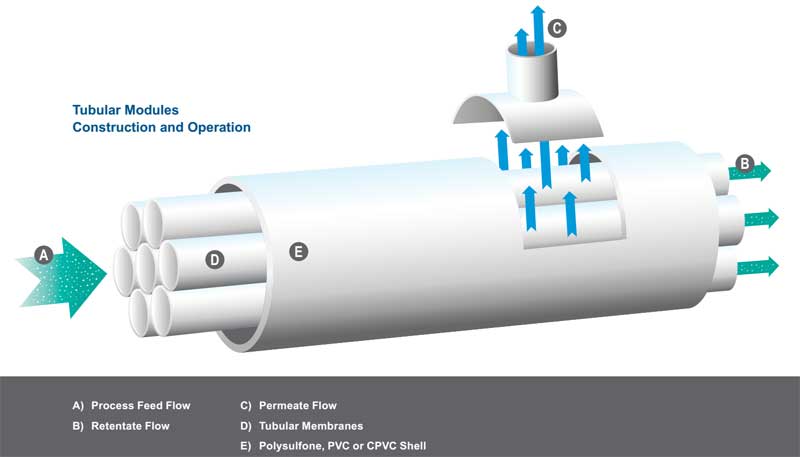

SUPER-COR® TUBULAR MODULES

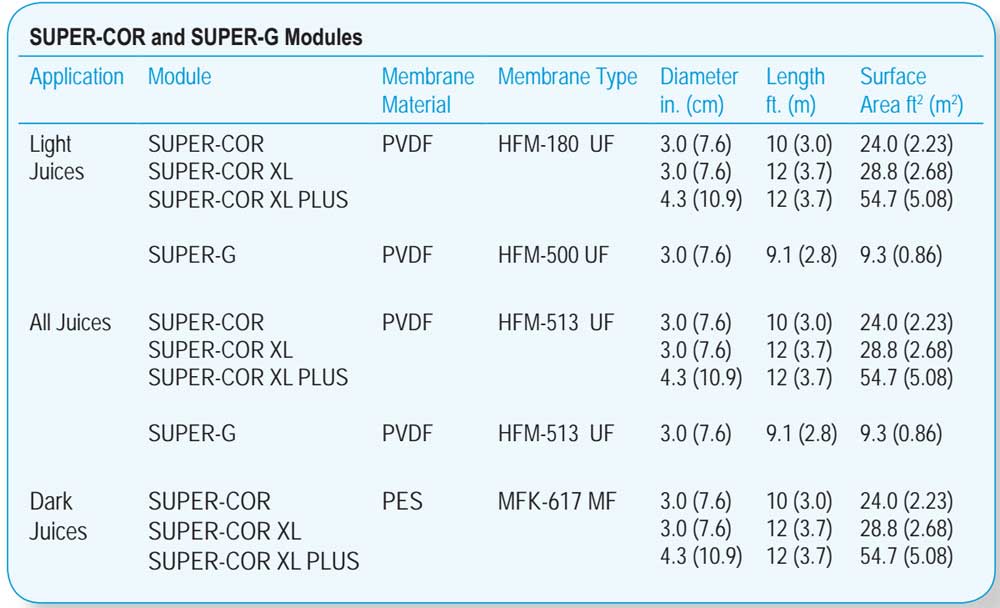

This multi-tubular product is designed to provide the most effective juice clarification process for a large variety of juice types. The SUPER-COR module design with ½” tubules is available in large diameters and lengths for the needs of industrial juice-production facilities. Small diameter modules are available for the replacement of existing systems and for small, boutique juice producers. SUPER-COR® membranes are available with different pore sizes for light or dark juice filtration, ensuring that only turbidity is removed, while color, flavor and aroma are maintained. Juice manufacturers around the world use the SUPER-COR product to clarify a diverse range of juices, including orange, apple, cranberry, grape, berries, carrots, açai and other exotic varieties.

SUPER-COR Series Backed by years of proven performance and exceptional durability, SUPER-COR ultrafltration modules, based on PVDF chemistry, enhance color, flavor, and stability without DE.

SUPER-COR microfiltration modules, based on PES chemistry, provide the highest molecular weight cut-off to allow color bodies to pass while retaining turbidity particles without a DE filter.

The result is higher yields, fewer maintenance concerns, and increased profit margins. Available in a variety of sizes, our latest models feature a robust backing structure to support the requirements of today’s juice processing plants, providing high flux and high recovery for all types of juices and production requirements.

SYSTEMS INFORMATION

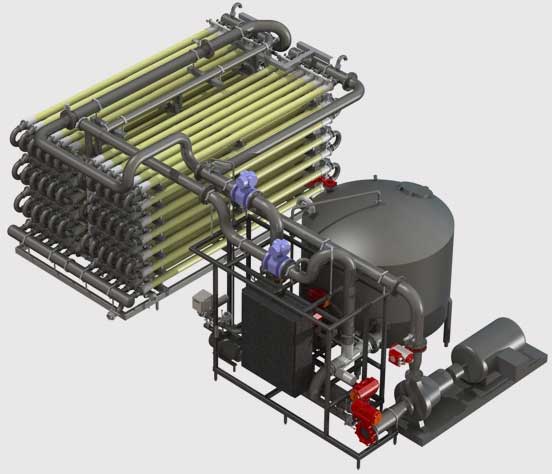

SUPER-COR® systems use KMS tubular SUPER-COR® ultrafiltration modules, primarily for filtration and clarification of juice. The systems are designed for fully automated operation, with user-friendly HMI for optimal performance per each client’s needs. They are easy to install and operate. Hundreds of KMS SUPER-COR® systems operate successfully in the juice-processing field, filtering dozens of juice types.

We can supply your operation with complete juice clarifcation solutions to meet a variety of processing requirements. The SUPER-COR and SUPER-G systems consist of modules designed in a series to maximize the ratio of membrane surface area to product volume, increasing juice throughput while minimizing energy usage. Easy to install, each system comes with pump, motor, controls, piping, valves,and instrumentation facilitating a simple, once-through batch process, up to 200 gpm (45 m3/hr).

The benefts are clear:

- Designed with plant and operators’ needs in mind.

- Fully automated with integral clean-in-place and permeate transfer.

- Automatic over-concentration protection feature prevents plugging.

- High output, small footprint.

DOWNLOAD DATASHEETS

SUPER-COR® 3" Diameter Multitube UF Modules

SUPER-COR XL 3" Diameter Multitube UF Modules

SUPER-COR XL PLUS 4.3" Diameter Multitube UF Modules