Description

Dairy-Pro® Elements

|

|

|

|

Download Process Separations _ KOCH MEMBRANE

For over 50 years, Koch Membrane Systems has pioneered the advancement of SPIRAL, HOLLOW-FIBER and TUBULAR filtration membranes and systems through innovation, research and development. From our state-of-the-art manufacturing and development facility in Wilmington, Massachusetts, we invest in technology with a focus on improving membrane formulations, element construction and process applications. In the interest of fully understanding your unique filtration requirements, our experienced team works side-by-side with you to learn your objectives, evaluate the options and provide best-practice advice for installing, operating and maintaining your membranes for peak performance and long-term efficiency.

Blister Resistant, Energy Efcient, Robust

Higher Productivity

Over 40 Years of Experience in Dairy Filtration

Koch Membrane Systems (KMS) is a global leader in innovative membrane fltration technologies. We’ve combined our 40 years of dairy industry experience with unmatched engineering and technical expertise to design Dairy-Pro® sanitary spiral wound elements specifcally for demanding dairy fltration applications.

Improved Blister Resistance, Longer Operating Life

Dairy-Pro elements utilize a blister resistant design and cross flow fltration technology to improve energy efciency, reduce operating costs, increase productivity, and decrease contamination risk. They are constructed to tolerate harsh cleaning requirements extending their operating life and optimizing every step of dairy membrane processing.

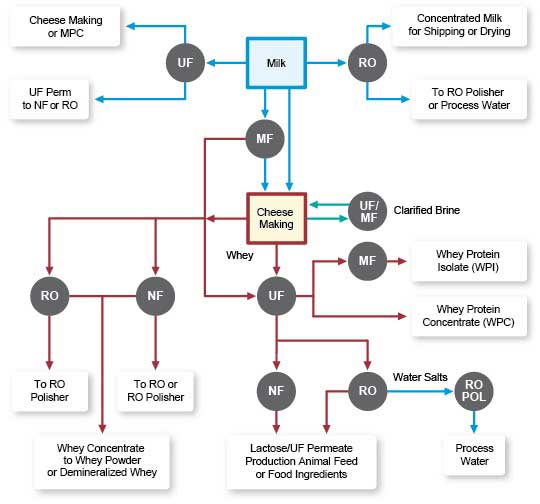

Dairy-Pro Technologies

• Microfltration (MF)

• Ultrafltration (UF)

• Nanofltration (NF)

• Reverse Osmosis (RO)

Benefts of Dairy-Pro

• Blister Resistant

• Energy Efcient

• High Productivity

• Long Operating Life

• Robust Construction

• USDA, FDA and 3A, EU, and Halal compliant

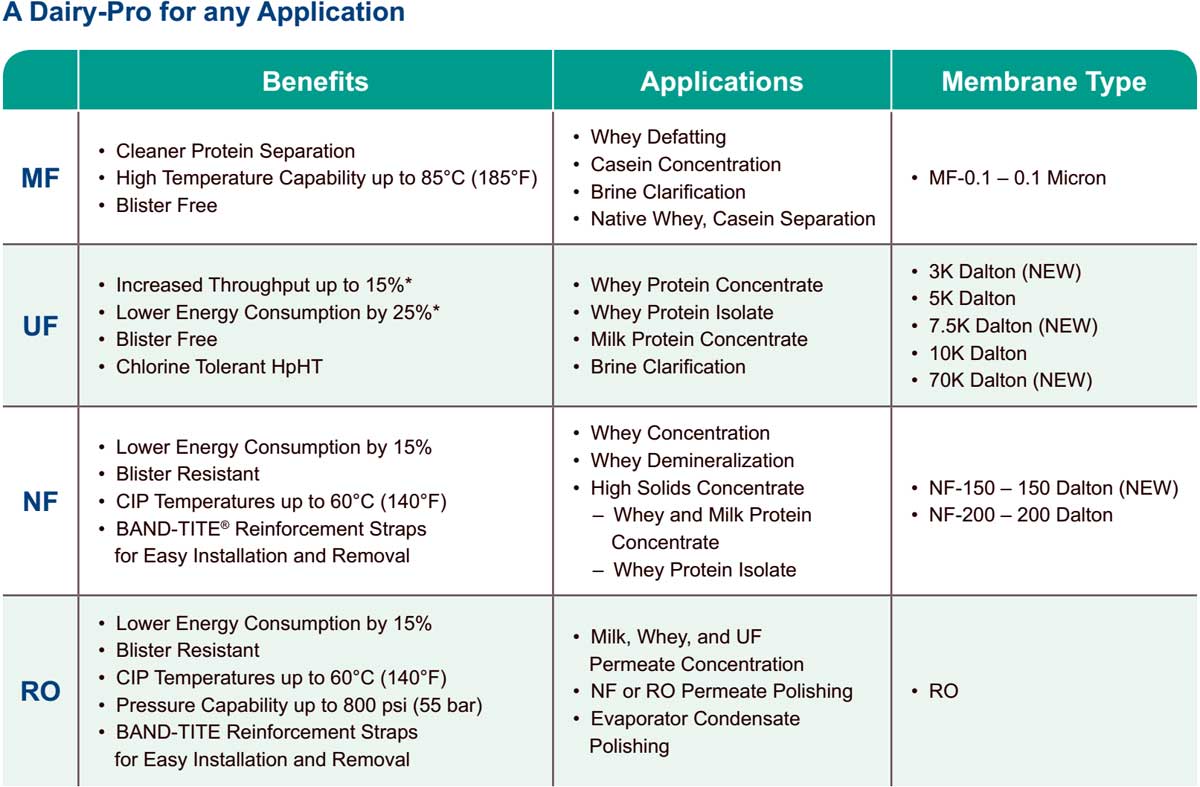

A Dairy-Pro for any Application

Features

REVERSE OSMOSIS & NANOFILTRATION

- Low energy

- Blister resistance

- High CIP temperatures

- High pressure capability

- BAND-TITE® technology

ULTRAFILTRATION

- High productivity

- Low energy

- Chlorine tolerant HpHT

- Blister free

- Large variety of membrane pore sizes

MICROFILTRATION

- High productivity

- Excellent separation properties

- High temperature capability

- Blister free

DOWNLOAD DATASHEETS

Dairy-Pro® MF Sanitary Elements

Dairy-Pro NF Sanitary Elements

Dairy-Pro RO Sanitary Elements

Dairy-Pro RO Polishing Elements

Dairy-Pro UF Sanitary Elements