Description

SelRO® _ THE CAUSTIC RECOVERY PROCESS

|

|

Download Process Separations _ KOCH MEMBRANE

Brochue hệ thống thu hồi NaOH _ Caustic Recovery _ Caustic-COR

For over 50 years, Koch Membrane Systems has pioneered the advancement of SPIRAL, HOLLOW-FIBER and TUBULAR filtration membranes and systems through innovation, research and development. From our state-of-the-art manufacturing and development facility in Wilmington, Massachusetts, we invest in technology with a focus on improving membrane formulations, element construction and process applications. In the interest of fully understanding your unique filtration requirements, our experienced team works side-by-side with you to learn your objectives, evaluate the options and provide best-practice advice for installing, operating and maintaining your membranes for peak performance and long-term efficiency.

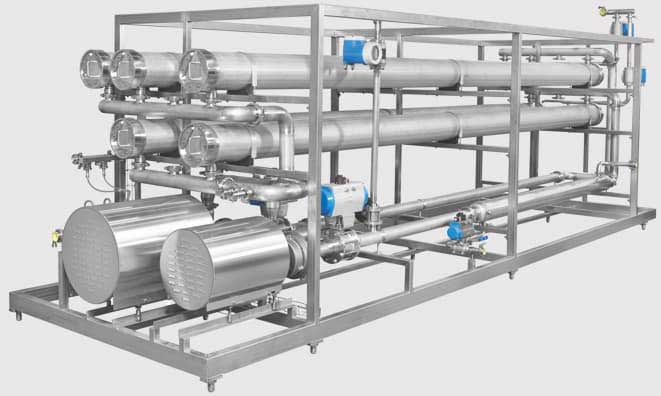

Causti-COR® Systems

How Much Is Your Caustic Really Costing You?

Membrane Technology Designed Specifcally for Caustic Recovery

Over 50 Years of Membrane Experience

Koch membrane systems (KMS) is a global leader in membrane fltration technologies with over 50 years of membrane experience and 20,000 system installations worldwide. We have applied our experence and expertise to develop our new Causti-COR® systems, designed specifcally to recover, purify and reuse caustic from food, beverage and industrial applications. These systems lower spending on caustic, reduce energy consumption, and are environmentally friendly to help your company comply with increasing stringent regulatory requirements.

SelRO®

The SelRO® chemically stable NF membranes are among our best-selling products, designed for robust performance and a long lifecycle. Commonly used in the pulp, paper, textile and other chemical industries, SelRO® elements are made to handle extreme acid and caustic conditions, and temperatures up to 160˚F (70˚C). Our pH stable spiral is the only product in the market with proven long-term compatibility in acid and caustic concentrations above 10%.

The SelRO family of spiral wound elements utilize a proprietary membrane developed by KMS using a highly crosslinked polymeric chemistry.

They demonstrate long membrane life while treating acids and bases with temperatures up to 160°F (70°C), and concentrations including:

- Sodium and potassium hydroxide (up to 20%)

- Sulfuric, nitric, hydrochloric, hydrofluoric and phosphoric acids or acid blends, up to 35%

- pH levels from 0-14

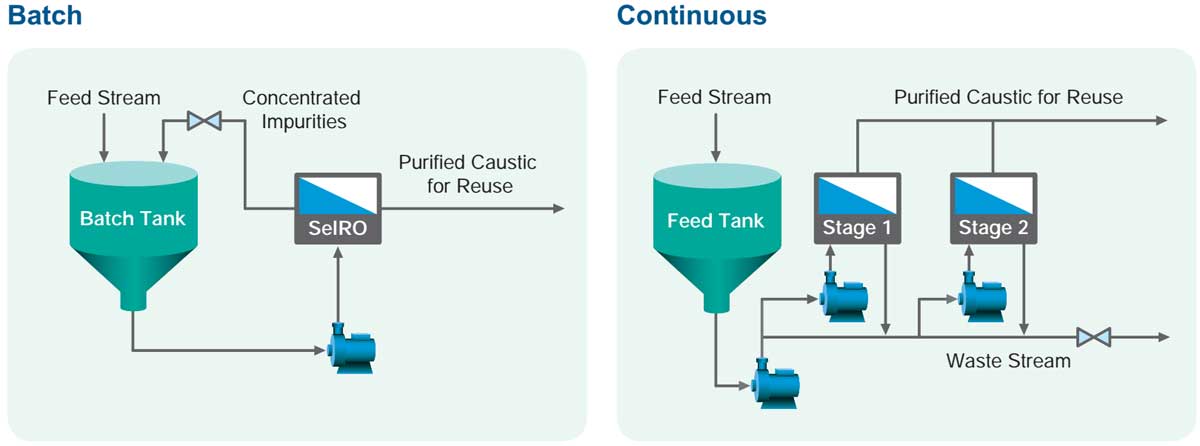

THE CAUSTIC RECOVERY PROCESS

- > 90% recovery

- > 90% COD reduction

- > 90% water and heat savings

- 80-90% hardness and carbonates reduction

- Colorless product

- Compact design

- Fast return on investment

- Modular design

SYSTEMS INFORMATION

Causti-COR® systems use the KMS SelRO® spiral-wound products for acid and caustic recovery in various industries, including pulp, paper, textiles, pharmaceuticals, food, beverages and more. Causti-COR® systems produce high-quality effluent while fostering environmental sustainability, saving significant chemical costs, and reducing wastewater volumes.

Causti-COR Systems

The KMS Causti-COR Nanofltration Membrane Systems offer a cost effective, environmentally friendly way to recover the expensive caustic solutions used to clean process equipment.

Causti-COR systems utilize our patented SelRO® membranes to recover up to 95% of caustic for reuse by removing low molecular weight organic and inorganic contaminants.

Benefts of recycling caustic

- Less spending on caustic and acid materials

- Reduction in efuent volume

- Reduced waste treatment costs

- Lower energy consumption

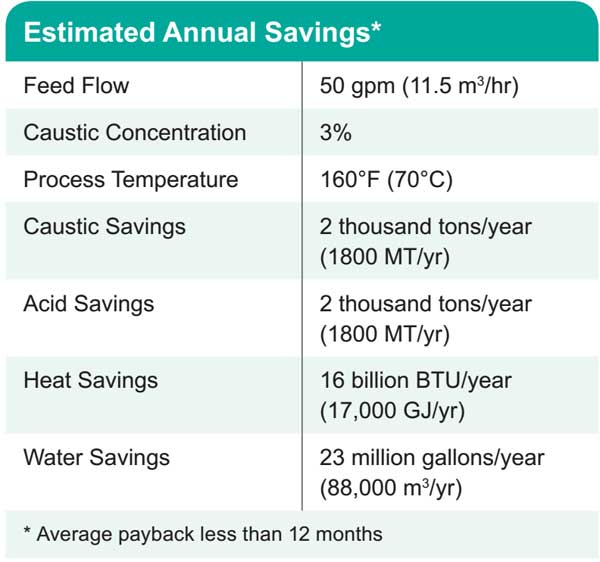

Estimated Annual Savings*

Caustic Systems

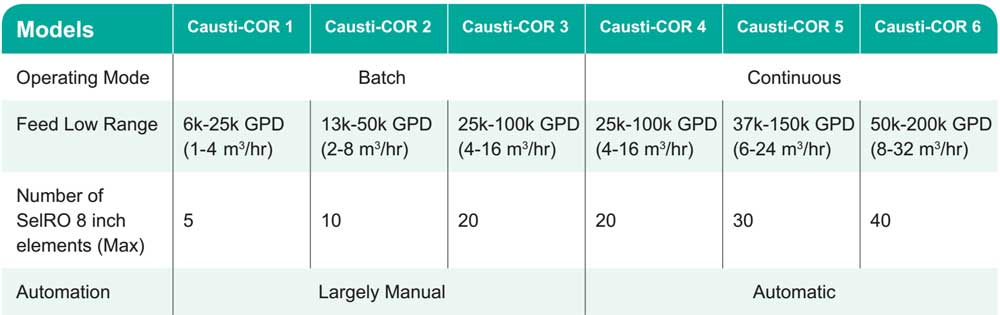

The Causti-COR® system family offers six models, including 3 small, simple to operate batch systems for small and medium flow rates between 1 and 15 m3/hr (10,000 – 100,000 GPD) and 3 larger, continuously

operated systems for medium and large feed flow rates between 4 and 32 m3/hr (25,000 – 200,000 GPD). Larger flow rates can be treated using custom-engineered systems.

Common Recovery Applications

- Pulp and paper

- Textile manufacturing

- Purifcation and mercerization

- Pharmaceutical

- Equipment cleaning

- Food processing

- Spent regeneration streams of resin columns and ion exchange operation

- Dairy, Food and Beverage

- Oil industry

DOWNLOAD DATASHEETS

SelRO® MPS-34 2.5" and 4" pH Stable NF Elements

SelRO MPS-34 8" pH Stable NF Elements

SelRO MPS-34 Sanitary 8" pH Stable NF Elements

SelRO MPS-36 2.5" and 4" pH Stable NF Elements

SelRO MPS-36 Sanitary 4” pH Stable NF Elements