Description

PURON MBR and PULSION MBR Modules

DOWNLOAD DATASHEETS

PULSION® MBR Submerged Hollow Fiber Modules

PULSION MBR Submerged Hollow Fiber Rows

PURON PSH Submerged Hollow Fiber Rows

PURON MBR Submerged Hollow Fiber Modules PSH330, PSH660 and PSH1800

PURON MBR Submerged Hollow Fiber Modules PSH95, PSH440, PSH520 and PSH1650

For over 50 years, Koch Membrane Systems has pioneered the advancement of SPIRAL, HOLLOW-FIBER and TUBULAR filtration membranes and systems through innovation, research and development. From our state-of-the-art manufacturing and development facility in Wilmington, Massachusetts, we invest in technology with a focus on improving membrane formulations, element construction and process applications. In the interest of fully understanding your unique filtration requirements, our experienced team works side-by-side with you to learn your objectives, evaluate the options and provide best-practice advice for installing, operating and maintaining your membranes for peak performance and long-term efficiency.

PURON MBR

The single-header ultrafiltration PURON membrane bioreactor changed industrial and municipal wastewater treatment. This patented module features reinforced PVDF hollow fibers that are fixed only at the bottom, virtually eliminating the clogging buildup of hair, fibrous materials and sludge solids. Solids and particulates, including bacteria, remain on the outside, while permeate is drawn through the membrane to the inside of the fibers. The aeration nozzle is centered in the fiber bundle to scour the entire fiber length, minimizing power consumption.

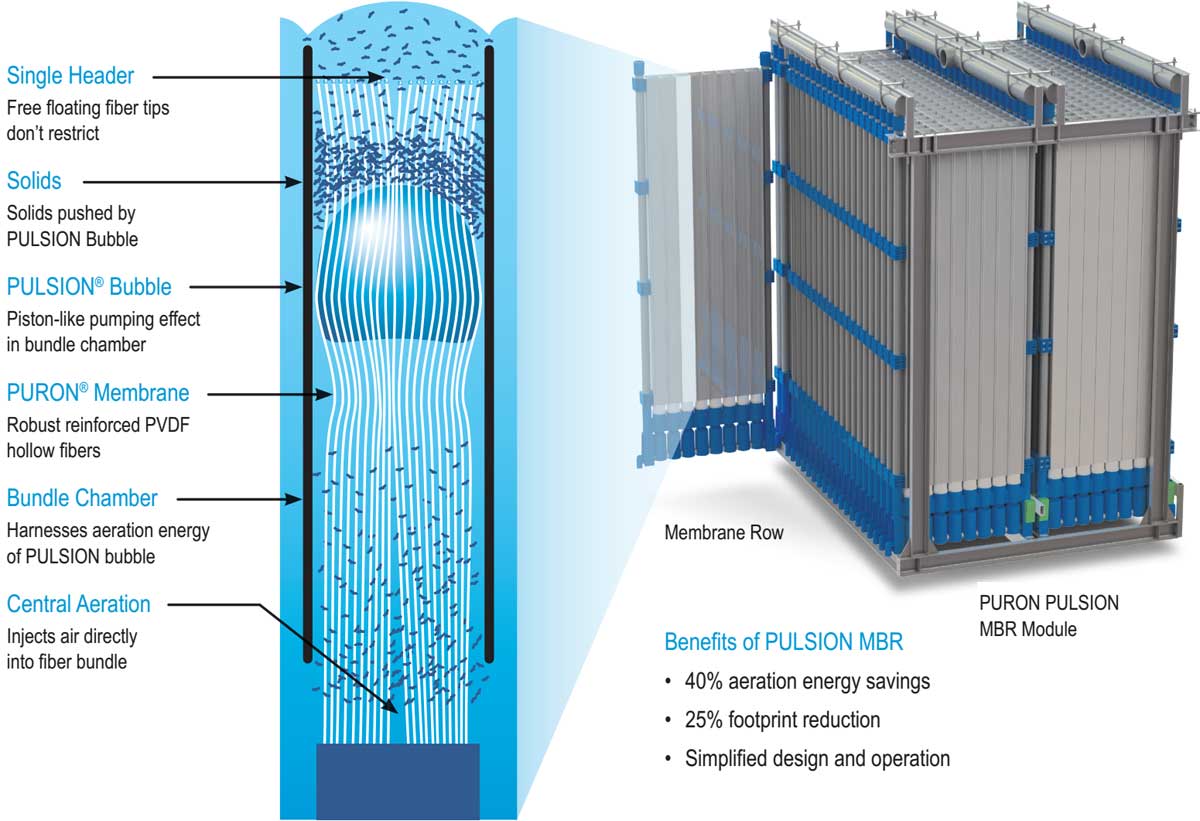

PULSION MBR

The next generation of PURON MBR, PULSION MBR modules offer up to 40% aeration energy reduction and 25% footprint reduction. This innovation pulses a large bubble through a chambered fiber bundle, creating a piston-like pumping action that results in lower air and aeration energy requirements than traditional scouring methods. Improved recirculation of mixed liquor in the membrane module boosts achievable fluxes and overall performance.

Optimized design and layout has reduced tank sizing while eliminating the need for air cycle valves. A minimized continuous air flow applied to the membranes has decreased the size of air delivery equipment by 50%, also reducing operation costs.

SYSTEMS INFORMATION

PURON® PLUS MBR systems, featuring our submerged PULSION® MBR modules, are pre-engineered membrane bioreactor (MBR) package plants. With capacities ranging up to 250,000 GPD, they are designed for both municipal and industrial wastewater applications, including food, dairy, beverage, leachate and produced water.

These skid-mounted systems offer a complete and cost-effective design. The virtually unbreakable high-performance PURON membrane provides consistent high-quality effluent. Coupled with a comprehensive biological system, the PURON PLUS MBR system can reduce BOD and nitrogen concentrations down to 5 and 10 mg/L respectively.

Features

- Braided fibers for no breaks and minimal downtime

- Crash-resistant air scouring

- High flux and reduced fouling

- Title 22-compli