Description

CÔNG NGHỆ MÀNG LỌC TRONG SẢN XUẤT SỮA

Membrane Filtration in the Dairy Industry

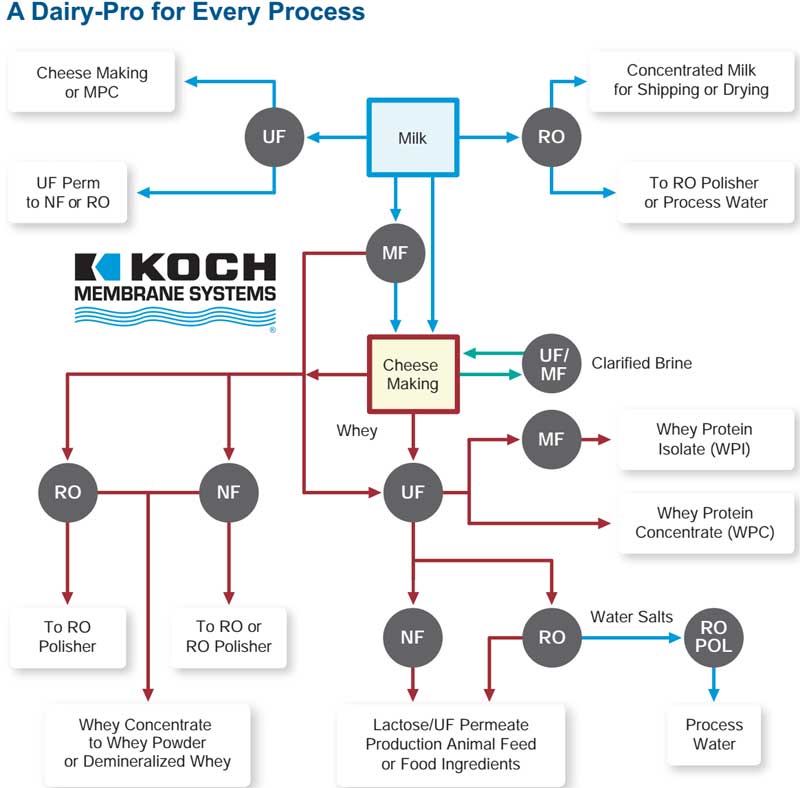

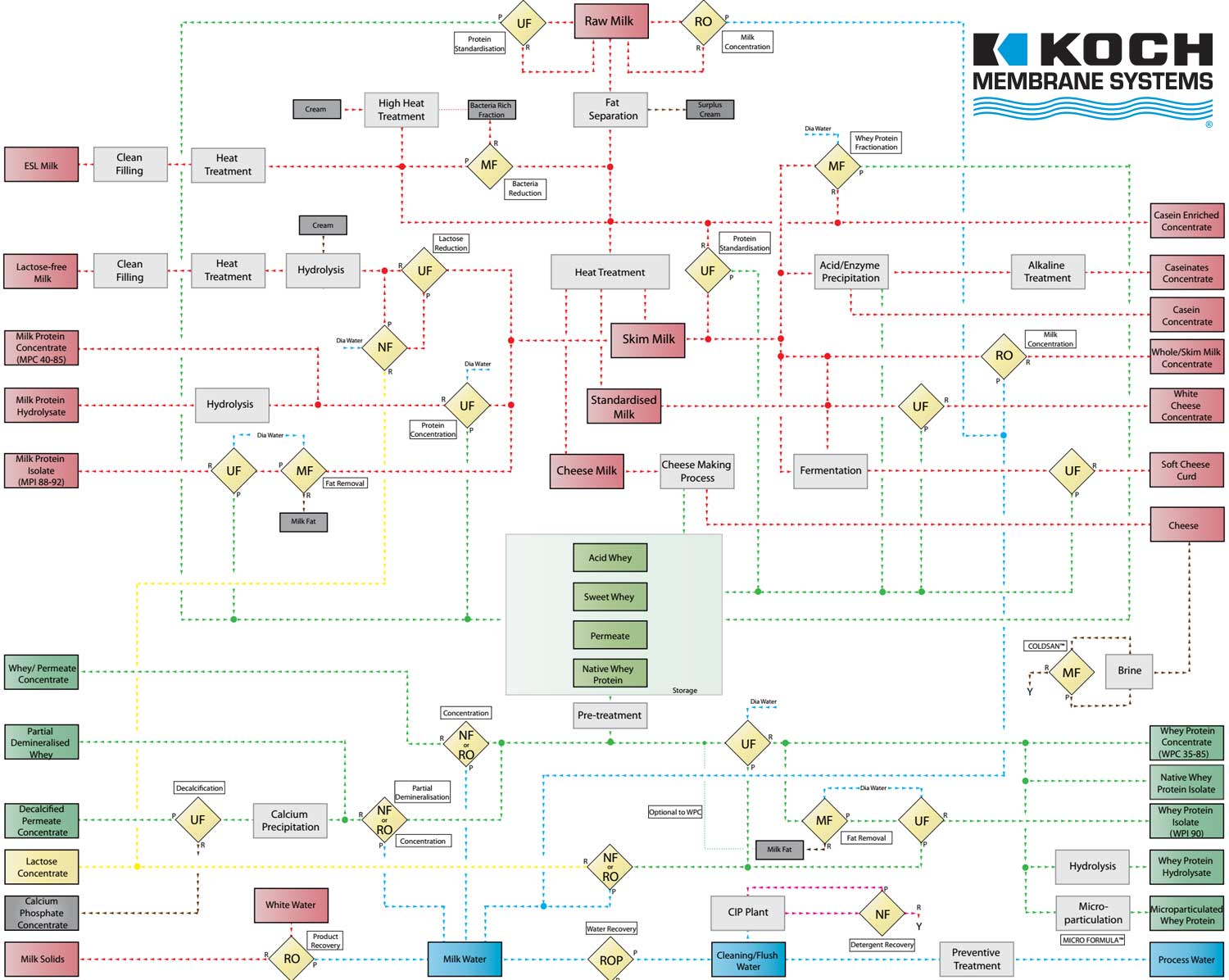

Download Process Separations _ KOCH MEMBRANE

Dairy Solutions

Dairy-Pro® Sanitary Spiral Wound Elements

Công ty Môi Trường Hành Trình Xanh hân hạnh là nhà nhập khẩu và phân phối độc quyền Công Nghệ Màng Lọc cho sản xuất Sữa KOCH - USA tại Việt Nam. Chúng tôi cam kết cung cấp sản phẩm và dịch vụ tốt nhất tới Quý Khách hàng.

Filtration for a Better Future là cam kết của chúng tôi và cũng là động lực thúc đẩy chúng tôi liên tục cải tiến công nghệ để tạo ra sản phẩm giá trị cao nhất cho khách hàng của mình.

Với trên 50 năm kinh nghiệm, Koch Membrane Systems (KMS) đã tiên phong trong việc nghiên cứu phát triển các loại Màng Lọc như: SPIRAL, HOLLOW-FIBER và TUBULAR.

KMS là công ty hàng đầu thế giới về Công Nghệ Màng Lọc với nhà máy sản xuất và trung tâm nghiên cứu hiện đại nhất được đặt tại Wilmington, Massachusetts (USA).

Ngoài ra, Chúng tôi đã cung cấp Màng RO, NF, UF, MF trên toàn thế giới với hơn 400 loại sản phẩm khác nhau. KMS cam kết sản phẩm và dịch vụ khách hàng tốt nhất, giúp đạt hiệu quả vận hành tối đa với chi phí tối thiểu.

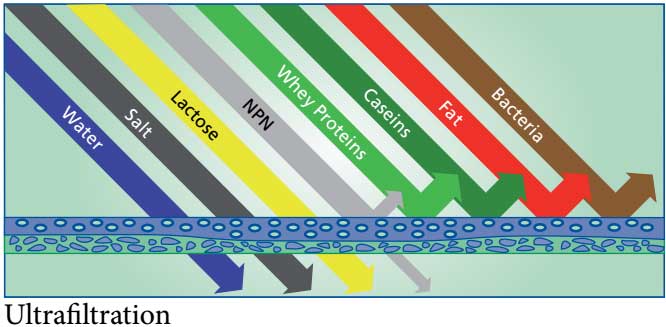

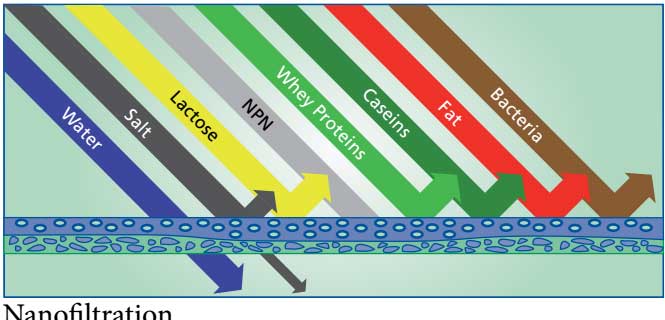

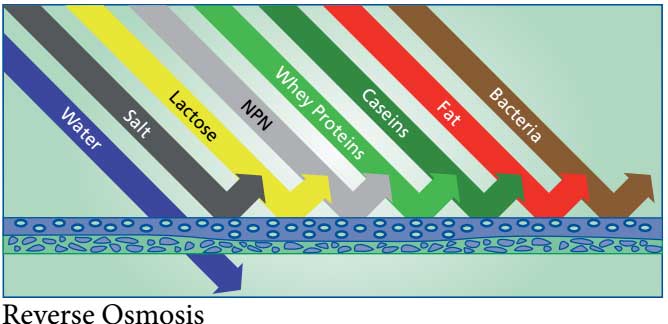

Membrane filtration is a separation process which separates a liquid into two streams by means of a semi-permeable membrane.The two streams are referred to as retentate and permeate. By using membranes with different pore sizes, it is possible to separate specific components of milk and whey. Depending on the application in question, the specified components are either concentrated or removed/reduced. Membrane filtration can basically be divided into 4 main technologies: / Lọc Màng là công nghệ tách rắn lỏng bằng Màng bán thấm, hai dòng gọi là Retentate và Permeate. Bằng cách sử dụng lỗ màng khác nhau có thể tách các thành phần Sữa và Đạm Sữa. Tùy thuộc vào ứng dụng cụ thể mà các thành phần được tập trung hoặc loại bỏ. Lọc Màng chia làm 4 loại chính:

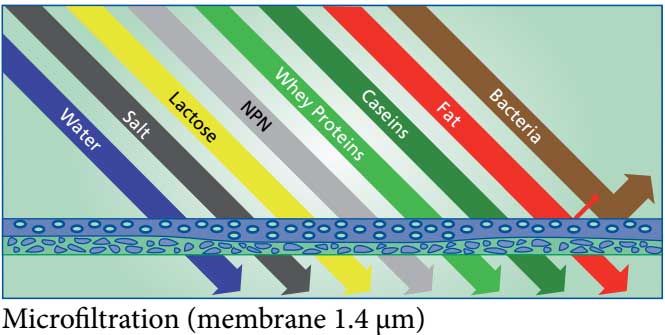

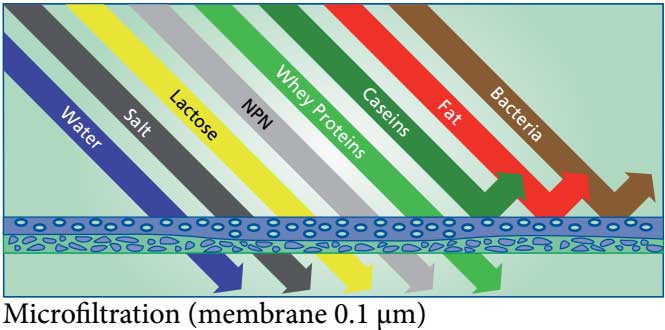

1. Microfiltration (Màng vi lọc MF)

Microfiltration is a low pressure-driven membrane filtration process, which is based on a membrane with an open structure allowing dissolved components to pass while most non-dissolved components are rejected by the membrane. In the dairy industry, microfiltration is widely used for bacteria reduction and fat removal in milk and whey as well as for protein and casein standardisation. / Trong ngành công nghiệp Sữa => Màng vi lọc MF được sử dụng rộng rãi để loại bỏ vi khuẩn và chất béo trong Sữa, cũng như Đạm, Protein, Casein.

|

|

Ứng dụng loại bỏ Vi khuẩn Bacteria / Bacteria Reduction

- ESL (Extended Shelf Life) Milk: Microfiltration is today widely used in the production of high-quality market milk and ESL milk. As opposed to traditional heat treatment where the microorganisms of the milk are inactivated and the chemical composition of the milk is changed,microfiltration physically removes bacteria, spores, dead cells and impurities from the milk, leaving practically no autolyzable cells and causing no undesired changes to the chemical composition of the milk. / trong sản xuất sữa thị trường chất lượng cao và sữa ESL. Trái ngược với công nghệ xử lý nhiệt truyền thống nơi các vi sinh vật của sữa bị bất hoạt và thành phần hóa học của sữa được thay đổi, Màng vi lọc MF loại bỏ vi khuẩn, bào tử, tế bào chết và tạp chất từ sữa, giúp cho Sữa không có tế bào autolyzable và không làm thay đổi thành phần hóa học của Sữa.

- Cheese Milk: Improvement of cheese milk can be achieved using microfiltration. The natural content of anaerobic spores in milk - such as clostridia - which can survive normal pasteurisation and cause undesired gas formation in the cheese, can be reduced by means of microfiltration. Furthermore, microfiltration can avoid or significantly reduce the addition of normal inhibitors (e.g. nitrate) thereby achieving preservative-free cheese and whey. / Sử dụng Màng vi lọc MF làm tăng chất lượng Phô Mai làm từ Sữa. Các bào tử vi sinh vật kỵ khí trong sữa - chẳng hạn như clostridia - có thể tồn tại trong quá trình thanh trùng bình thường và tạo ra sự hình thành khí không mong muốn trong Phô Mai, có thể giảm bằng phương pháp vi lọc. Hơn nữa, vi lọc có thể tránh hoặc giảm đáng kể việc bổ sung các chất ổn định (ví dụ: nitrat) do đó đạt được Phô Mai và Whey không có chất bảo quản.

- Milk & Whey Powders: Microfiltration can improve the quality of milk and whey powder considerably through a reduction of bacteria and spores. As a consequence, heat treatment can be kept at an absolute minimum which - among other things - contributes to a preservation of the functional properties of the whey proteins in the powder. / Màng vi lọc MF có thể cải thiện chất lượng sữa và bột whey thông qua việc giảm vi khuẩn và bào tử nấm. Vì thế giảm thiểu thanh trùng bằng nhiệt => góp phần bảo tồn các tính chất của protein whey trong bột.

- Cheese Brine Sanitation: The chemical and microbiological quality of the cheese brine used for salting cheese products is critical for the final quality of the cheese. As brine may contain undesired microorganisms, cheese brine has traditionally been subjected to different types of treatment such as heat treatment, kieselguhr filtration, UV treatment or even addition of preservatives. Microfiltration can easily replace any of these processes avoiding the many disadvantages involved.

Milk Protein Fractionation

- Casein Standardisation of Cheese Milk: When it comes to obtaining process control and quality, a uniform and stable production process is of the highest importance to any cheese manufacturer. By using microfiltration, it is possible to fractionate casein and whey proteins and thereby to standardise the concentration of casein in the cheese milk to obtain the correct ratio between casein and fat. / bằng cách sử dụng Màng vi lọc MF tách casein và whey protein trong sữa phô mai để có được tỷ lệ chính xác giữa casein và chất béo.

- Casein Production: Microfiltration can fractionate milk proteins into casein and whey proteins. The fractionated casein can be used in the production of high-quality casein and caseinate or in the production of special casein-rich milk products. The by-product of this fractionation(permeate) contains whey proteins in their natural form which are unaffected by heat treatment, enzymes (rennet) or bacteria (starter cultures). This by-product is especially suited for the production of high-quality liquid stabiliser, Whey Protein Concentrate (WPC) and Whey Protein Isolate (WPI). / Microfiltration có thể phân đoạn protein sữa thành casein và whey protein. Các casein phân đoạn có thể được sử dụng trong sản xuất casein chất lượng cao và caseinate hoặc trong sản xuất các sản phẩm sữa giàu casein đặc biệt. Các sản phẩm phụ của phân đoạn này chứa các protein whey ở dạng tự nhiên của chúng không bị ảnh hưởng bởi xử lý nhiệt, enzyme hoặc vi khuẩn.

Milk Fat Removal / Loại bỏ chất béo từ Sữa

- Protein Isolate: In the production of protein isolate - e.g. Milk Protein Isolate (MPI) or Whey Protein Isolate (WPI) - where a protein level of more than 90% in the total solids is required, the fat content constitutes a limiting factor. The milk fat is concentrated to a very high level, and in order to achieve the final protein concentration, removal of the milk fat is required. Microfiltration is the obvious solution for performing this fat removal.

2. Ultrafiltration (Màng siêu lọc UF)

Ultrafiltration is a medium pressure-driven membrane filtration process. Ultrafiltration is based on a membrane with a medium-open structure allowing most dissolved components and some non-dissolved components to pass, while larger components are rejected by the membrane. In the dairy industry, ultrafiltration is used for a wide range of applications such as protein standardisation of cheese milk, powders, fresh cheese production, protein concentration and decalcification of permeates as well as lactose reduction of milk. / Trong ngành công nghiệp Sữa, Màng siêu lọc UF được sử dụng cho một loạt các ứng dụng như tiêu chuẩn protein của sữa, pho mát, bột, sản xuất phô mai tươi, nồng độ protein và decalcification từ dòng thấm cũng như giảm lactose sữa.

Protein Concentration

- Cheese Milk: Ultrafiltration followed by a traditional cheese production process can be used for pre-concentration of cheese milk. In this way, the protein level of the cheese milk is kept constant which contributes to an optimisation of the utilisation of the cheese-making equipment. The by-product of the ultrafiltration process (permeate) is perfectly suited for lowering the protein content of other products such as e.g. skim milk powder. / Màng Siêu Lọc UF để cô đặc sữa trong sản xuất Phô Mai, dòng Permeate có thể được sử dụng làm sản phẩm sữa tách béo.

- Milk Protein Concentrate: Ultrafiltration is commonly used in the production of Milk Protein Concentrate (MPC) where it can lead to an increase of the protein content in the total solids. The by-product (permeate) is perfectly suited for lowering the protein content of other products such as e.g. skim milk powder. / Màng Siêu Lọc UF để cô đặc sữa trong sản xuất Sữa giày Protein, dòng Permeate có thể được sử dụng làm sản phẩm sữa tách béo.

- Whey Protein Concentrate: Whey Protein Concentrate (WPC) is obtained using ultrafiltration on different whey types (sweet, acid or casein) or different types of permeates from microfiltration of milk. Depending on the required protein concentration level, different ultrafiltration techniques can be applied (e.g. dilution with water also known as diafiltration). The final composition of the WPC depends on several factors such as the original composition, the level of concentration, the membrane itself and the processing parameters. The by-product (permeate) - mainly containing lactose - is suitable for further valuable processes.

Protein Standardisation

- Milk: Ultrafiltration can be used to standardise and increase the protein content of milk without the use of additives such as milk powder. Protein-enriched milk has additional health benefits and improved taste, and is also very suitable for the production of fermented milk products (yoghurt, crème fraîche, kefir etc.). To optimise the protein utilisation in the dairy, the ultrafiltration permeate can be used for lowering the protein content of the milk.

- Cheese Milk: As the protein content of milk varies significantly depending on the season and the breed of cow in question, it can be difficult to maintain a constant protein level of the milk. Protein standardisation using ultrafiltration can eliminate these protein variations, ensuring a uniform cheese production process and an optimisation of the utilisation of the cheese-making equipment.

Decalcification (Calcium Removal)

- Ultrafiltration can be used as a superior separation unit in a decalcification unit for the decalcification of RO or preferably NF pre- concentrated permeates for lactose production. As calcium-phosphate is highly insoluble, it can be easily removed by means of the UF technology following a thermal precipitation process. Applying this technology will in general result in high-quality lactose, where the reduction of calcium-phosphate will lead to a higher lactose yield and lower mineral content in the final lactose product as well asgenerally improved evaporator running times. Depending on the UF separation unit‘s concentration degree, calcium can be refined into a natural calcium-phosphate product.

Fresh Cheese

- White Cheese: Ultrafiltration is widely used in the production of white cheese where the whole milk is concentrated to 34-40% total solids by means of ultrafiltration. The retentate (concentrate) from the ultrafiltration process is pasteurised and mixed with starter culture, rennet and salt and subsequently filled directly into the packaging, where the entire cheese production process then takes place. The process is very simple and increases the yield by more than 20% compared to traditional production methods.• Fermented ProductsFermented products is a term used as a common denominator for fresh cheese products like quark, cottage cheese, fromage frais, cream cheese and many more. By including ultrafiltration in the production of fermented cheese, it is possible to adjust the product in order to achieve the exact combination of consistency, texture and flavour. A standardisation of the protein level prior to fermentation for these types of products will result in several benefits such as yield increase and a reduction in the amount of acid whey.

Lactose Reduction

- Lactose-free Milk: In the production of lactose-free milk, ultrafiltration plays an important role in achieving a sensory experience similar to that of fresh milk. Before the milk undergoes an enzymatic process (hydrolysis), most of the lactose is removed by means of ultrafiltration.

3. Nanofiltration (Màng lọc Nano NF)

Nanofiltration is a medium to high pressure-driven membrane filtration process. Generally speaking, nanofiltration is another type of reverse osmosis where the membrane has a slightly more open structure allowing predominantly monovalent ions to pass through the membrane. Divalent ions are - to a large extent - rejected by the membrane. In the dairy industry, nanofiltration is mainly used for special applications such as partial demineralisation of whey, lactose-free milk or volume reduction of whey. / Trong ngành công nghiệp sữa, lọc nano chủ yếu được sử dụng cho các ứng dụng đặc biệt như khử khoáng một phần whey, sữa không lactose hoặc giảm thể tích whey.

Concentration

- Whey and Permeate: Nanofiltration of whey and permeates will reduce the mineral content – especially sodium and potassium chlorides (monovalent ions) – in these products, and since both whey and permeates in most cases need to pass through a concentration step priorto further processing, nanofiltration becomes a very attractive technology, as it combines volume reduction with partial demineralisation in one and the same process step.

- Volume Reduction: In order to achieve savings on transportation costs, it is possible to apply nanofiltration for volume reduction (concentration) of whey and permeates. With nanofiltration technology, higher flux rates can be achieved, making nanofiltration a financially attractive alternative compared to other technologies, e.g. reverse osmosis.

- Lactose: Lactose is mainly produced from whey and permeates, and nanofiltration plays an important role in a modern lactose production facility. By applying nanofiltration, lactose can be concentrated before further processing - i.e. crystallisation. Further, nanofiltration will reduce the amount of minerals which in turn will provide a more efficient crystallisation process and will consequently result in a lactose product with a higher degree of purity.

Partial Demineralisation

- Demineralised Whey: When producing demineralised or non-hygroscopic whey powder where low lactose and mineral contents are required, nanofiltration can be applied as an economically attractive supplement to electrodialysis and ion-exchange technologies. Depending on the type of whey, the demineralisation degree can reach more than 30%, making the electrodialysis and ion- exchange processes more efficient.

- Demineralised Whey Powders: Demineralised whey powders (DWP D35, D50, D70, D90) intended e.g. for use in the production of baby food, can - depending on the degree of demineralisation - be manufactured by means of nanofiltration and combinations of ultrafiltration and nanofiltration as well as nanofiltration combined with electrodialysis (ED) before evaporation and spray drying.

Lactose Reduction

- Lactose-free Milk: Nanofiltration is a commonly applied technology for the production of high-quality lactose-free milk products. As the membrane layer in the nanofiltration technology rejects lactose but allows passage of various minerals, the milk will maintain most of its original composition and the consumer will get a sensory experience which is almost similar to that of fresh milk.

Detergent Recovery

- Purification of CIP (Cleaning-In-Place) Solutions: In processing plants where the detergent consumption is high, nanofiltration can be applied in order to achieve a purification of the CIP solutions used (e.g. NaOH and HNO3). Removal of impurities and reduction of the COD level enable a very long recycling period, where the loss of detergents is reduced to a minimum. In order to maintain a constant concentration level, priming will still be required.

4. Reverse Osmosis (Màng thẩm thấu ngược RO)

Reverse Osmosis is a high pressure-driven membrane filtration process which is based on a very dense membrane. In principle, only water passes through the membrane layer.In the dairy industry, reverse osmosis is normally used for concentration or volume reduction of milk and whey, milk solids recovery and water reclamation. / Trong ngành công nghiệp sữa, thẩm thấu ngược thường được sử dụng để cô đặc hoặc giảm khối lượng sữa và đạm sữa, phục hồi chất rắn trong sữa và xử lý nước.

Pre-concentration

- Supplement to Evaporation: Reverse osmosis can be applied as a supplement to evaporation. If a new evaporation line is required or an existing line is to be extended, huge savings can be obtained by joining the two technologies. Reverse osmosis is a very efficient way of removing water from the milk or whey prior to the evaporation stage. By installing a reverse osmosis plant upstream of an existing evaporator, the capacity of the evaporator can be increased considerably depending on the application and type of evaporator in question.

Concentration

- Total Solids Increase: Reverse osmosis can be used to concentrate skim milk or whole milk in order to increase the total solids content. This is – among other things - relevant for fermented products. As reverse osmosis practically removes only water, the technology can be applied as an energy-efficient alternative to evaporation or the addition of milk powder, which are the most common ways of increasing the total solids content of milk.

- Volume Reduction: Reverse osmosis can be applied to reduce the volume of milk or whey - e.g. for saving transportation costs. Volume reduction based on reverse osmosis is an alternative to nanofiltration.

- Product Recovery: In order for a modern dairy production facility to be able to meet the many demands – both economical and environmental - put forward by the surrounding society, waste recovery has become increasingly important. From the first cleaning flush, sweet “white water” is collected in a dedicated collection tank. The sweet “white water” is concentrated to the required total solids content by applying reverse osmosis, and the recovered solids can subsequently be returned to the production process - e.g. to increase the total solids in yoghurt milk. The by-product of this concentration process - water - can also be utilised as described in the following section.

Water Recovery

- Water Recovery and “Polishing” Permeates originating from reverse osmosis or nanofiltration processes as well as condensates from evaporators are practically water. With an additional reverse osmosis treatment normally referred to as “Polishing”, this water can be purified and re-used for cleaning purposes. With further heat treatment or UV light treatment, it is even possible to use the water as process water.

- Effluent Control: Some production facilities – such as large whey processing sites – have an excess amount of water which must be discharged. As water disposal is normally connected with emission taxes depending on the COD level among other factors, subjecting the water to a reverse osmosis process can lower the COD level and reduce emission taxes significantly.

Blister Resistant, Energy Effcient, Robust

Higher Productivity

Over 40 Years of Experience in Dairy Filtration

Koch Membrane Systems (KMS) is a global leader in innovative membrane fltration technologies. We’ve combined our 40 years of dairy industry experience with unmatched engineering and technical expertise to design Dairy-Pro® sanitary spiral wound elements specifcally for demanding dairy fltration applications.

Improved Blister Resistance, Longer Operating Life

Dairy-Pro elements utilize a blister resistant design and cross flow fltration technology to improve energy efciency, reduce operating costs, increase productivity, and decrease contamination risk. They are constructed to tolerate harsh cleaning requirements extending their operating life and optimizing every step of dairy membrane processing.

Dairy-Pro Technologies

• Microfltration (MF)

• Ultrafltration (UF)

• Nanofltration (NF)

• Reverse Osmosis (RO)

Benefts of Dairy-Pro

• Blister Resistant

• Energy Efcient

• High Productivity

• Long Operating Life

• Robust Construction

• USDA, FDA and 3A, EU, and Halal compliant

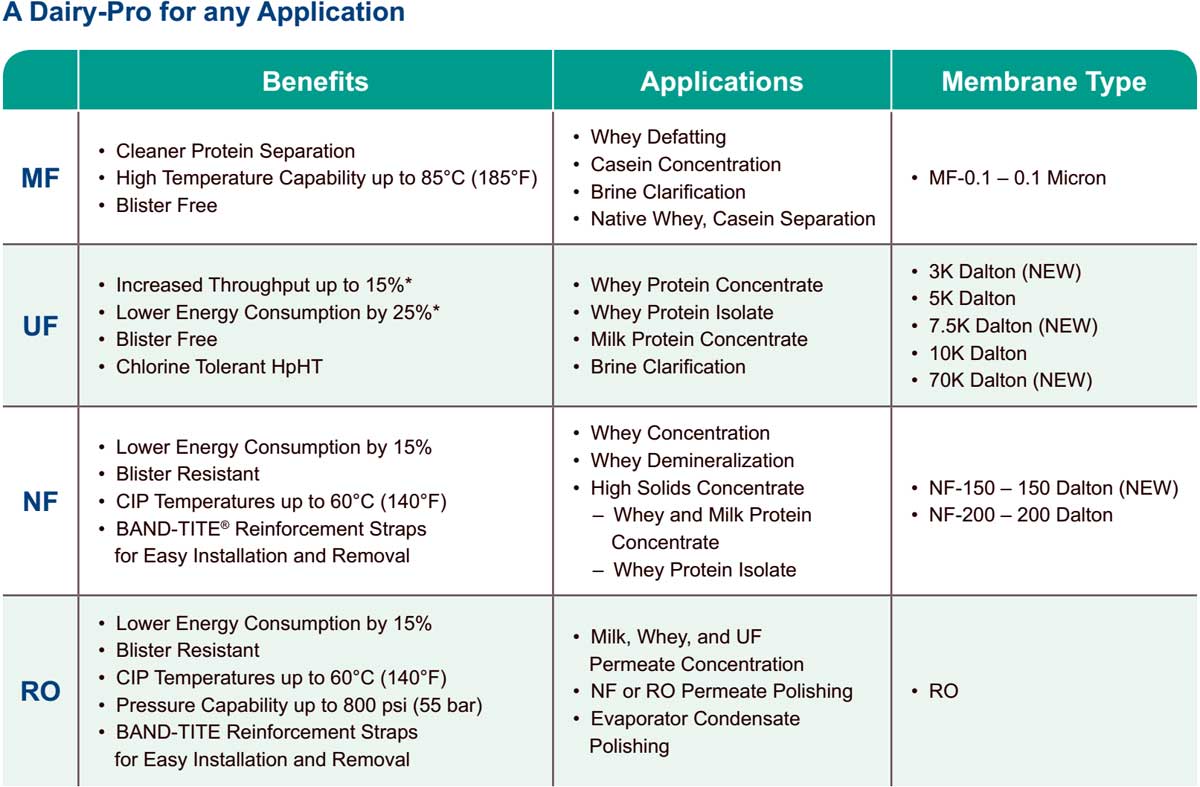

A Dairy-Pro for any Application

Features

REVERSE OSMOSIS & NANOFILTRATION

- Low energy

- Blister resistance

- High CIP temperatures

- High pressure capability

- BAND-TITE® technology

ULTRAFILTRATION

- High productivity

- Low energy

- Chlorine tolerant HpHT

- Blister free

- Large variety of membrane pore sizes

MICROFILTRATION

- High productivity

- Excellent separation properties

- High temperature capability

- Blister free

DOWNLOAD DATASHEETS

Dairy-Pro® MF Sanitary Elements

Dairy-Pro NF Sanitary Elements

Dairy-Pro RO Sanitary Elements

Dairy-Pro RO Polishing Elements

Dairy-Pro UF Sanitary Elements